Welcome

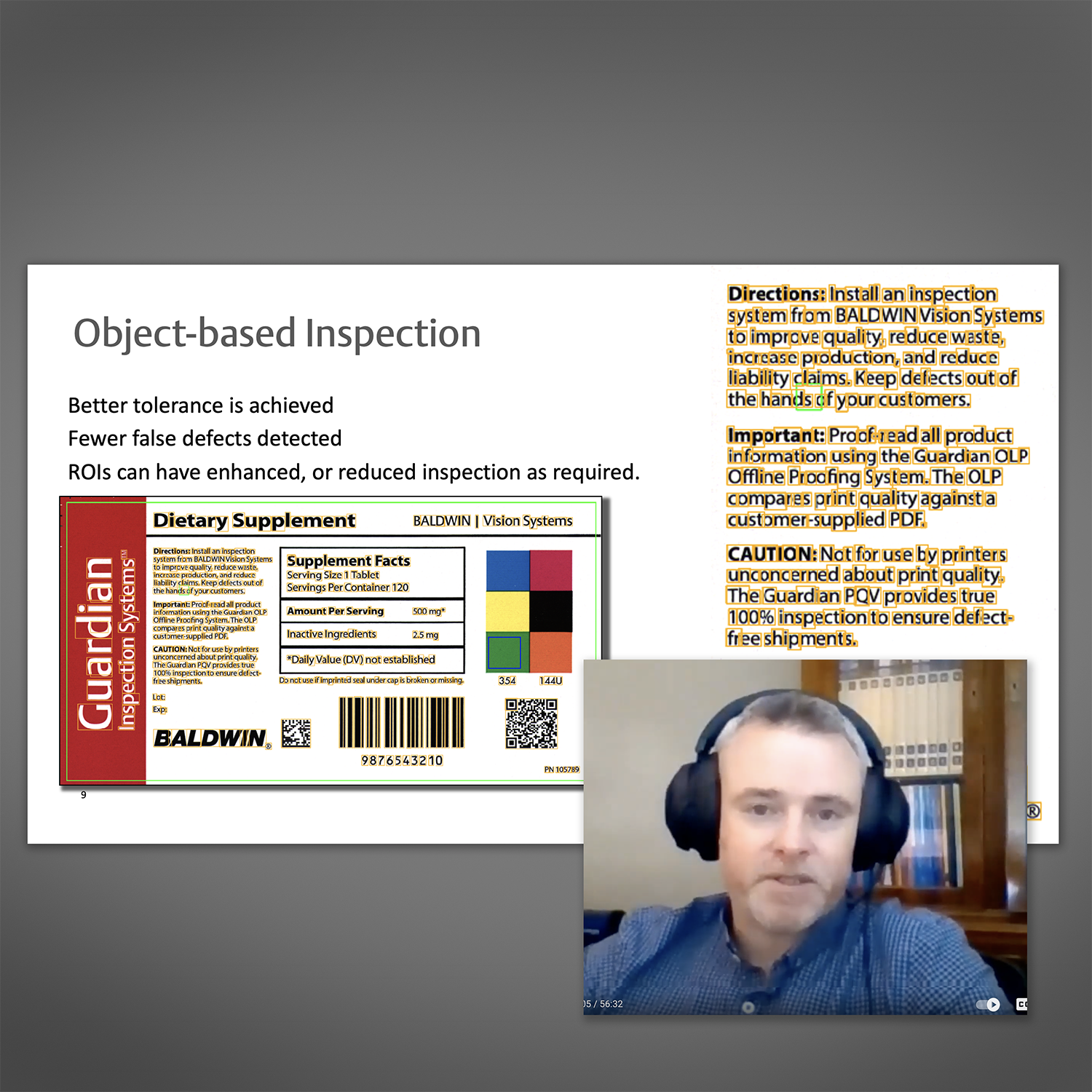

Baldwin Vision Systems designs and manufactures the print industry’s most advanced color management and print inspection technology solutions to help you achieve print quality perfection. By automating your workflows, we help you manage increasingly complex requirements and exacting standards. We have robust, profit-generating solutions for Packaging & Converting, Security Printing, Commercial Web Offset, and Newspaper printers. Read more >